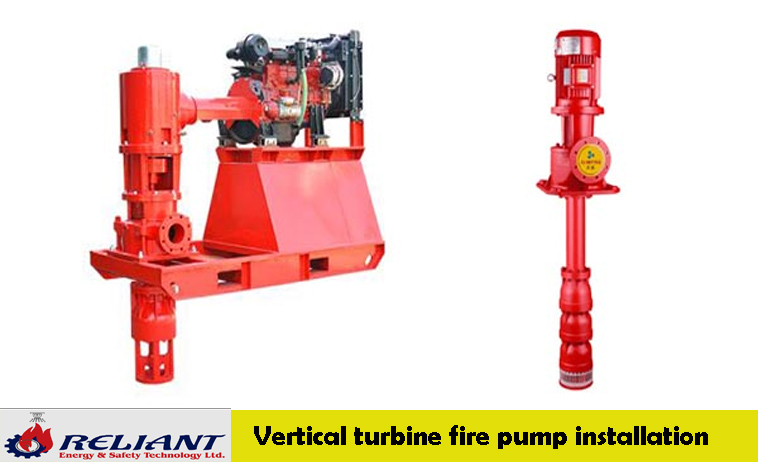

Installing vertical turbine fire pumps is one of the most important things that can be done to make fire safety systems in buildings and factories stronger. People make these special pumps so that they can provide a steady flow of water in case of a fire. This makes sure that the flames are quickly put out. Putting in a vertical turbine fire pump is a very exact and important job that needs skill and close attention to detail. It is one of the most important things that keeps people, property, and other valuables safe from fire. This piece will talk about the importance of vertical turbine fire pumps, how to Vertical turbine fire pump installation correctly, and the main points that show how important they are for making places safer during fires.

What is a vertical turbine pump?

One type of centrifugal pump that is used to get water or other fluids from a well or reservoir that is underground is called a vertical turbine pump. It has a straight shaft with several impellers stacked on top of each other. The impellers move the liquid from the bottom of the tank to the top when the pump is turned on. Vertical turbine pumps work well when a submerged water source needs to be quickly brought to the top. This can happen in industrial processes, municipal water supply systems, and agricultural irrigation. Because they are vertical, they are perfect for deep well installations and places with limited room.

How to install a vertical turbine pump

Putting in a vertical turbine pump can be hard and needs careful planning and attention to detail. These pumps are often used for a wide range of tasks, including watering plants, farming, and industry processes. Here are the steps you need to take to set up a vertical turbine pump:

Note: Before you start, make sure you have all the tools and equipment you need and have read the manufacturer’s instructions for the pump type you have. Different manufacturers may have different installation instructions, so always do what the producer says.

1. Put safety first:

- Make sure that the pump doesn’t have any power coming from any sources.

- Wear the right gloves, safety glasses, and other personal protective equipment (PPE).

2. Select the Installation Site:

- Pick a spot that is stable, level, and easy to get to for upkeep.

- Make sure the pump is lined up correctly with the water source or well.

3. Get the well or sump ready:

- Clear out the well or sump of any dirt or other things that are blocking it.

- Make sure you get the depth of the well right, because that will tell you how long the pump column and drop pipe need to be.

4. Put together the parts of the pump:

- Put together the parts of the vertical turbine pump, such as the motor, bowl, impellers, shaft, and column pipe. For the right way to put something together, look at the manufacturer’s directions.

5. Put the pump down into the well:

- Carefully lower the pump unit into the well or sump, making sure it is level and in the middle.

- Use the right bolts or clamps to attach the pump to the well casing and keep it from moving.

6. Connect the empty pipe to the drop pipe:

- Make sure the connection between the drop pipe and the pump’s discharge head is safe.

- In the well or pit, extend the drop pipe to the depth you want.

- Join the drop pipe to the outflow pipe and route it to the right place.

7. Hookup for electricity:

- To connect the motor’s wires to the power source, follow the manufacturer’s instructions and the rules for your area.

- Make sure there is good grounding to avoid electrical dangers.

8. Look at the alignment:

- Make sure the pump is centered and set correctly in the well or sump.

- Make sure that the impellers don’t touch the well casing’s sides.

9. Get the pump ready:

- Depending on the type of pump you have and what you want to use it for, you may need to fill the pump’s case with water before turning it on.

10. Turn on the pump:

- Turn on the pump slowly and listen for any strange sounds or movements as it works.

- Change the settings and speed of the pump as needed to get the flow rate you want.

11. Test and Keep an Eye on It:

- Do a performance test to make sure the pump is working at the right pressure and capacity.

- Check the pump often for any signs that it’s not working right and do the regular maintenance that the maker suggests.

Keep in mind that the way you install a pump may be different based on the model and the use. Always follow the directions that came with the product, and if you’re not sure about any part of the installation process, talk to a professional. For a vertical turbine pump to work well and last a long time, it needs to be installed and maintained correctly.

Preparation of Foundations for Pumps

The base where the pump is put must be strong enough to hold the weight of the pump itself plus the weight of the fluid inside it. If you have weak foundations or foundations that are on unsteady ground, they can move out of place, vibrate, or even fail completely. So, make sure that the foundation has already been cleared and that the load calculations have been done. For the base plate or discharge head to have a stable and rigid support, the foundation’s mass should be at least five times that of the pumping equipment’s rotating part. This is important no matter where the pump is put: over a pit, over a well, or into a suction bucket.

Rigging and Lifting of Pumps

For most installations, the job site should have the right overhead lifting tools to move the driver, the whole pump (without the driver), or the pump’s heaviest part when the pump is being installed or taken out. All safety measures linked to health and safety must be carried out in line with the method statement and risk assessment. There should be enough space to fit the longest part of the pump that needs to be handled, along with the rigging. There should be slings, chains, and shackles of the right size to connect to the lifting lugs (eyes). When lifting lugs are not available, eye-bolts must be used to move pump parts.

Conclusion

In conclusion, installing a vertical turbine fire pump is an important part of making sure that buildings are safe and protected against fire risks. Following the manufacturer’s instructions exactly, keeping the angle straight, and following safety rules are all important parts of the process. To make sure the pump is ready for emergencies, it needs to be checked and monitored on a regular basis. By carefully installing and maintaining these pumps, we improve our ability to react quickly and effectively to fire emergencies, protecting people and property.