Choose the right fire pump is critical. For ensuring the safety of your building. They supply the necessary water pressure and flow to fire sprinkler systems, as mandated by NFPA 20, the standard for installing stationary pumps for fire protection. Selecting the right fire pump involves careful consideration of several factors, including type, size, capacity, and power source. In this comprehensive guide, we’ll walk you through everything you need to know to make an informed decision.

Types of Fire Pumps

Selecting the right fire pump for your building begins with understanding the different types available. Each type is designed for specific scenarios and building requirements. Below is a detailed overview of the most common types of fire pumps, their advantages, and the situations where they perform best.

Visit our detailed guide to know more about essential fire safety tips for manufacturing plants.

End Suction Fire Pumps

Description:

End suction fire pumps are characterized by their compact design, with the suction and discharge nozzles positioned perpendicular to each other. They are a single-stage centrifugal pump and are widely used in fire protection systems for their simplicity and efficiency.

Advantages:

- Simple Design: Easy to install and operate, making it a popular choice for basic fire protection needs.

- Cost-Effective: Among the most economical fire pumps, both in terms of initial investment and maintenance.

- Easy Maintenance: Straightforward access to pump components for repair and inspection.

Best For:

- Low-rise buildings such as schools, small offices, or warehouses.

- Applications with moderate water demand and pressure requirements.

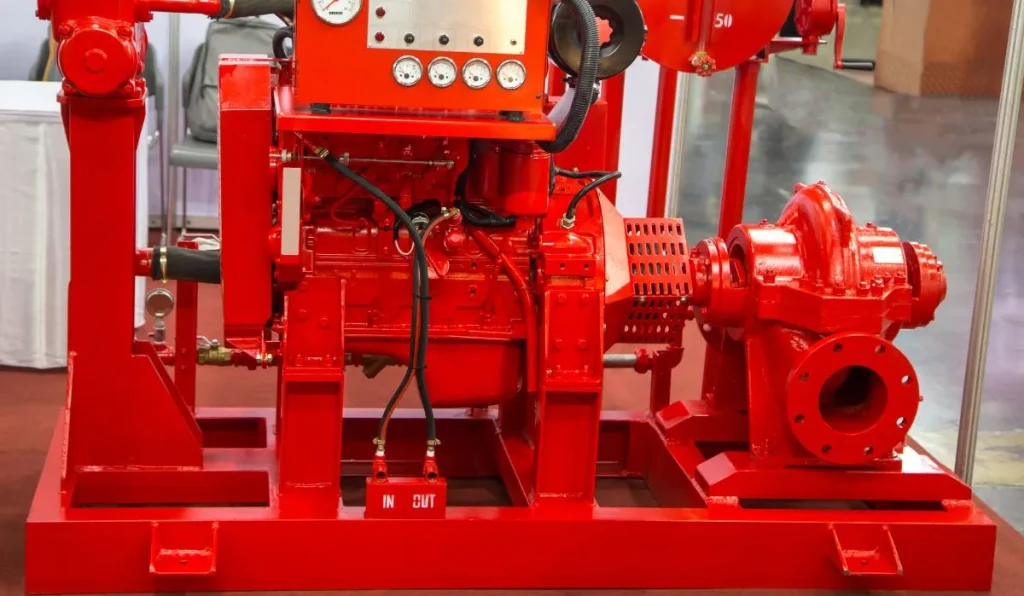

Horizontal Split Case Fire Pumps

Description:

Horizontal split case fire pumps have a robust design with a horizontally split casing that allows easy access to internal components. They are typically dual-suction pumps, capable of handling large volumes of water efficiently.

Advantages:

- Highly Efficient: Capable of delivering high flow rates with minimal energy consumption.

- Easy to Maintain: The split case design allows technicians to access internal parts without disturbing the pump’s alignment or piping.

- Reliable Performance: Well-suited for continuous, high-capacity operation.

Best For:

- Medium to high-rise buildings such as apartment complexes, hospitals, and large commercial facilities.

- Applications requiring high water flow and pressure for extensive fire protection systems.

Vertical Turbine Fire Pumps

Description:

Vertical turbine fire pumps are specially designed for scenarios where the water source is located below ground level, such as in wells, reservoirs, or tanks. These pumps use a series of impellers to lift water from the source to the fire protection system.

Advantages:

- Ideal for Deep Water Sources: Designed to draw water from below ground, making them perfect for remote locations or unique water supply challenges.

- Space-Saving Design: Vertical orientation reduces the footprint, making it suitable for tight spaces.

- Durable and Reliable: Performs well under challenging conditions, with a long service life.

Best For:

- Buildings with space constraints or where the water source is underground.

- Industrial facilities, power plants, or remote areas without direct access to municipal water supplies.

Inline Fire Pumps

Description:

Inline fire pumps are compact, vertical pumps where the suction and discharge nozzles are aligned, allowing them to fit seamlessly into existing piping systems. They are a popular choice for buildings with space limitations.

Advantages:

- Compact and Lightweight: The vertical design minimizes space requirements and simplifies installation.

- Energy-Efficient: Reduces energy consumption, making it an environmentally friendly option.

- Easy Integration: Fits directly into existing pipelines without significant modifications.

Best For:

- Small to medium-sized buildings such as retail stores, restaurants, or small office buildings.

- Applications where installation space is limited or retrofitting into an existing system is necessary.

Steps to Choose the Right Fire Pump

- Gather Fire Water-Supply Information: Understand the source of water supply (e.g., municipal, tank, or well) and its characteristics, such as available flow and pressure.

- Calculate Required Flow: Determine the flow rate needed for the fire protection system, ensuring compliance with design standards.

- Calculate Required Pressure: Assess the total pressure needed, accounting for factors like elevation changes, pipe friction losses, and the minimum pressure required at the sprinkler heads.

- Calculate Pressure Boost: Identify the additional pressure required by subtracting the available pressure from the total pressure required.

- Select a Pump Based on Flow Demand: Choose a pump where the required flow falls between 100% and 150% of the pump’s rated flow for optimal performance.

- Ensure Sufficient Pressure Boost: Verify that the pump’s performance curve provides adequate pressure boost at the desired flow rate.

Determining the Size and Capacity

Choosing the correct size and capacity is critical for ensuring adequate fire protection. This involves:

Assessing Water Demand

Water demand is determined by the design of your sprinkler system, including:

- Number of sprinkler heads.

- Type of sprinkler heads.

- Area and density of coverage.

Calculating Pressure Requirements

Pressure needs depend on:

- Elevation differences within the building.

- Friction losses in the piping.

- Minimum residual pressure required for effective sprinkler operation.

Performing a hydraulic analysis or consulting with a fire protection engineer is essential to ensure your fire pump meets these requirements.

Pro Tip:

For example, a standard office building classified as light hazard occupancy may require a pump capacity of 500 GPM at 65 PSI. However, specific calculations should be performed for accurate results.

Power Source Options

The power source is another critical consideration when choosing a fire pump. Each option has unique benefits and limitations:

Electric Motors

- Advantages: Low noise, low emissions, easy operation, and maintenance.

- Disadvantages: Dependence on a stable power grid, which may fail during emergencies.

Diesel Engines

- Advantages: Reliable and independent of external power sources, ideal for long-duration operation.

- Disadvantages: Higher maintenance needs, larger space requirements, and noise levels.

Steam Turbines

- Advantages: High efficiency and durability.

- Disadvantages: Rarely used due to high initial costs and complex operation requirements.

Choosing the Right Power Source

Consider factors like building location, budget, and redundancy needs. For enhanced reliability, many installations use dual power sources to ensure uninterrupted operation.

Additional Features to Consider

To maximize the efficiency and reliability of your fire pump system, consider the following features:

- Controllers: Ensure the pump starts automatically during a fire.

- Jockey Pumps: Maintain system pressure and reduce wear on the main pump.

- Anti-corrosion Coatings: Protect components from rust and extend lifespan.

Why Reliant-Est is Your Trusted Fire Pump Partner

At Reliant-Est, we go beyond simply supplying fire pumps. Our focus is on delivering tailored fire protection solutions designed to meet the unique needs of your building. Unlike competitors, we offer expert consultation, top-tier equipment, and unparalleled after-sales support. Choosing Reliant-Est means choosing safety, reliability, and efficiency.

Why Reliant-Est Stands Out

- Expert Consultation: Our team works closely with you to understand your building’s unique requirements and recommend the best fire pump solutions.

- Premium Equipment: We only offer fire pumps that meet or exceed international standards, ensuring optimal performance and reliability.

- Comprehensive Support: From installation to maintenance, Reliant-Est provides end-to-end services to ensure your fire protection system operates flawlessly.

- Customer-Centric Approach:We prioritize your safety and satisfaction, making us the trusted choice for fire protection solutions.

For more information on fire safety services, visit our best fire safety consultant in Bangladesh page

Conclusion: Choose the Right Fire Pump

Choosing the right fire pump for your building is a complex but crucial process. By understanding the types, sizes, capacities, and power sources of fire pumps, you can ensure that your fire protection system operates effectively during emergencies. At Reliant-Est, we’re committed to helping you make informed decisions and providing top-notch fire safety solutions.

Visit Reliant-Est to learn more about our fire pump options and services. Let’s protect what matters most—together.

FAQs

Q1. What is the primary purpose of a fire pump?

A fire pump provides the necessary water pressure and flow to fire sprinkler systems, ensuring effective fire suppression in buildings.

Q2. How do I determine the right fire pump size for my building?

You need to conduct a hydraulic analysis of your fire sprinkler system to calculate the required water flow (GPM) and pressure (PSI). Consulting a fire protection engineer can help ensure accuracy.

Q3. Can I use an electric motor for my fire pump in areas with frequent power outages?

While electric motors are common, a diesel engine-powered fire pump may be more reliable in areas prone to power failures. Dual power sources can also be considered for redundancy.

Q4. What maintenance does a fire pump require?

Regular maintenance includes checking pump alignment, inspecting seals, testing flow rates, and ensuring the power source (electric, diesel, or steam) is functioning correctly.

Q5. Why should I choose Reliant-Est for fire pumps?

Reliant-Est offers expert guidance, premium fire protection equipment, and exceptional after-sales support, ensuring your system operates reliably and meets safety standards.

Q6. What is the difference between jockey pumps and main fire pumps?

Jockey pumps maintain system pressure during normal operations to prevent frequent activation of the main fire pump, which operates only during fire emergencies.